Visit Hauschild Engineering exhibition stand #103 at the

2021 Adhesive & Sealant Expo at the ASC Annual Convention on Wednesday October 27, 2021 from 2:00 to 5:30 p.m.,

Omni Orlando Resort ChampionsGate

400 2nd Street

ChampionsGate, Florida

United States

Hauschild shows its original Hauschild SpeedMixer® and demonstrates bubble-free mixing of sealants and adhesives.

—————————————————–

Press information

Air does not bond and seal

Rapid, bubble-free mixing of sealants and adhesives by way of centrifugal force

In the case of some materials, bubbles in the mix are annoying, while with others they are fatal to performance: adhesives and sealants, for example, do not tolerate air at all. Electronic components must be sealed, potted, and bonded in a safe, effective, and repeatable manner. Professional grade centrifugal mixers such as the Hauschild SpeedMixer® deliver homogeneous, reproducible mixing and packaging results – without any further processing.

The possible applications of this centrifugal mixer are as diverse and multifaceted as the product world itself: Different liquids and pastes, pastes with powders, powders with powders and other combinations of liquids and powders can be mixed. Materials with different chemical and physical properties can also be mixed to form new sealants and adhesives.

Bubble-free thanks to special mixing technique

During the mixing process, the rotation of the mixing cup in two different directions and the combination of centrifugal forces naturally removes voids and micro-bubbles, even in cartridges. In most cases, there is no need for an additional degassing cycle as there is when using conventional mixing techniques or processing tools. For special cases when vacuum mixing is absolutely necessary (such as heat cured or space grade materials), the Hauschild SpeedMixer® is available with vacuum mixing technology. Programmable cycles ensure identical, reproducible mixing of each and every batch. This saves time, eliminates process variability, and maximizes pot life.

No cleaning required

The Hauschild SpeedMixer® mixes without blades by spinning closed disposable cups. This means that cleaning and the use of cleaning chemicals can be entirely eliminated. The capacity of the mixing cups and mixing buckets ranges from a few grams to ten kilograms, and from a few millilitres to 16 litres nominal capacity – depending on how large the batch is to be.

More info: www.hauschild-speedmixer.de

Hauschild YouTube channel: https://www.youtube.com/channel/UCs9jdLhro1rPgRZ3Lr-Nu1A/videos

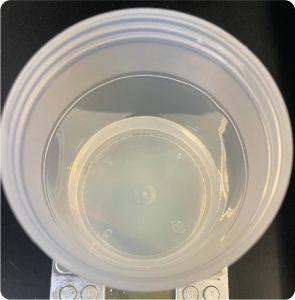

Photo (Hauschild Engineering): Hauschild SpeedMixer® mixes homogeneous adhesives and sealants in a few minutes

Photo (Lohnpack GmbH, Filling and packing service – www.lohnpack.info): Silicone adhesive bevore the mixing

Photo (Lohnpack GmbH, Filling and packing service – www.lohnpack.info): Silicone adhesive after mixing with Hauschild SpeedMixer®

About Hauschild Engineering:

The family-owned company Hauschild Engineering employs around 40 people and has been developing and producing the Hauschild SpeedMixer® at its headquarters in Hamm/Germany since 1974, selling it directly or with partners all over the world.

The original Hauschild SpeedMixer® offers perfect mixing results from a few grams or milliliters up to ten kilograms or sixteen liters. The machines are mostly used in laboratories that mix substances as part of their research and development work, as well as by companies that require small batch mixes for quality assurance.

Within few minutes, different liquids can be mixed with pastes or powders, pastes with powders, powders with powders, and substances with different chemical and physical properties – all without the use of stirring tools. The Hauschild SpeedMixer®, including all components, are manufactured according to a highest-quality standards – made in Germany.

US distributor contact details of Hauschild Engineering:

Hauschild SpeedMixer Inc.

37735 Enterprise Ct, Suite 300

Farmington Hills, MI 48331

USA

Mr. Davide Davi (CEO Americas)

Phone: +1 (877) SPDMXER

Fax: +1 (469)581-9981

Web: www.hauschild-speedmixer.de

eMail: info.us@hauschild-speedmixer.com

Press Contact

Mareike Boccola

Hauschild GmbH & Co KG (Hauschild Engineering)

Waterkamp 1, 59075 Hamm, Germany

Phone: +49 2381 482050

Fax: +49 2381 4820517

Web: www.hauschild-speedmixer.de

eMail: m.boccola@hauschild-speedmixer.com